|

|

|

||||

Contents: How To, Main Page

Step 4 Lets do some clean up now that the structure of the lower jaw is complete.

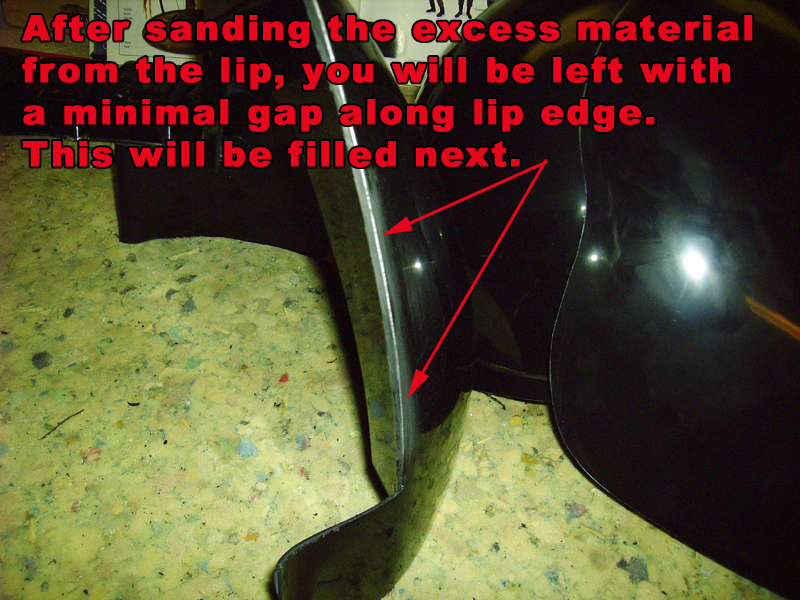

Image 8 (Jaw Cleanup) After sanding the excess material from the lip (as shown in Image 1 and 2) we have a relatively clean and sharp edge to work with, but we still have a fine gap between the lip plate and lower jaw...if you are as meticulous with this stuff as I am, this will not suffice; therefore....

...we move to this next task.

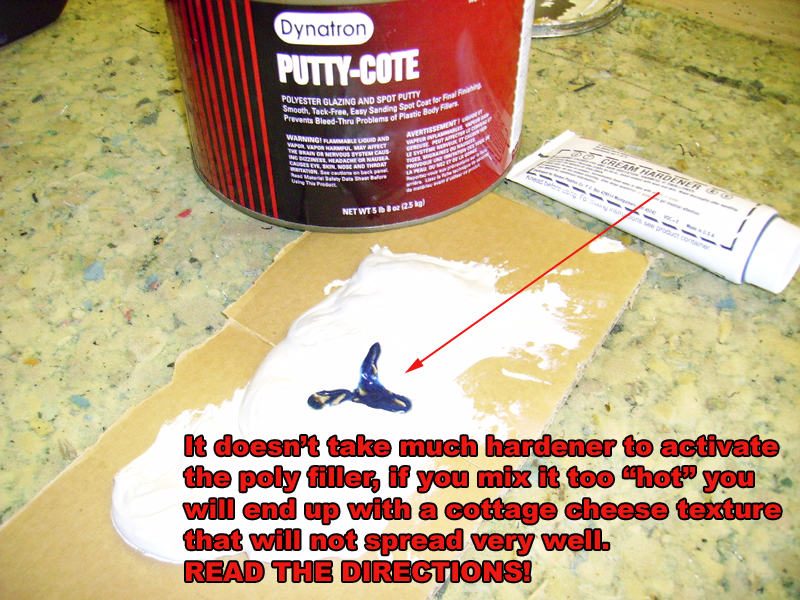

Image 9 (Jaw Cleanup) cont. Filling that void is not as tough as you would think, provided you have a little patience and don't rush it. You will certainly not need an entire gallon of body filler to do what comes next. I was building 6 of these so I mixed more than what you will see below. The amount required is all dependant on how much gap you left in the steps of construction above...if you decide to fill the gap at all. Note the product description on the can?

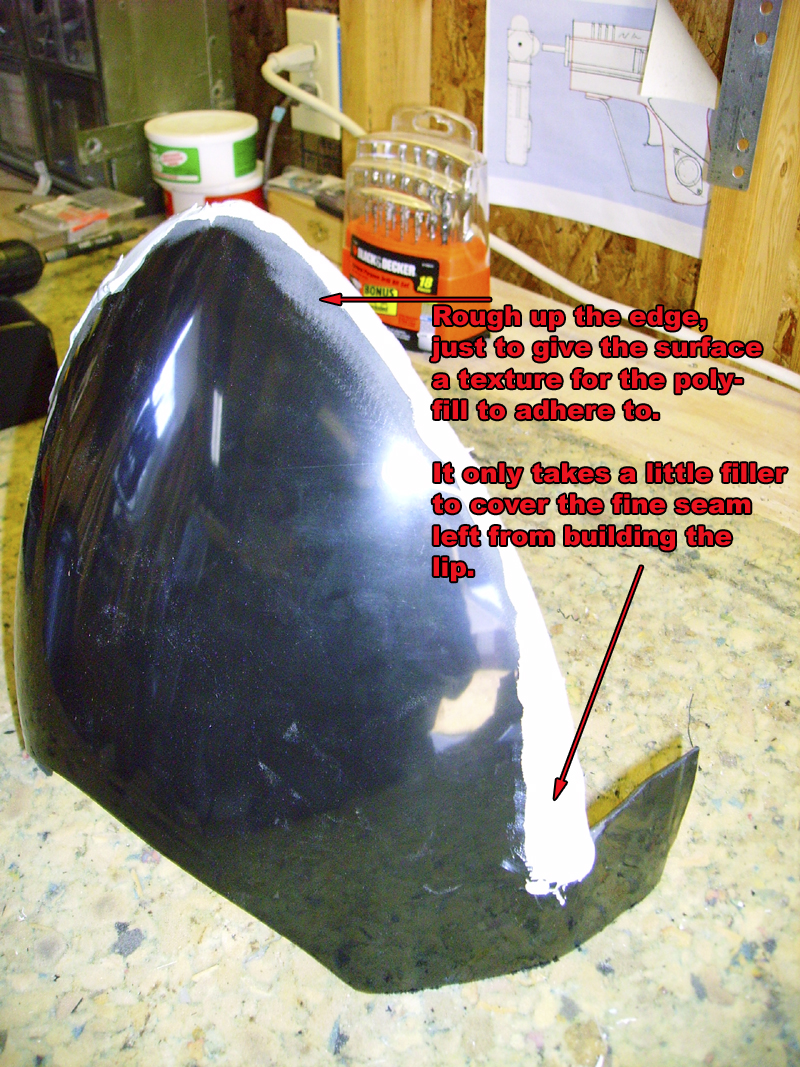

Image 10 (Jaw Cleanup) cont. Before you apply the poly-fill make sure you rough up the surface a little to give the material something to hold onto. In addition to a bondable surface, this will prevent a rough edge when sanding the material later. In other words, if you don't prepare the surface properly, you will not have a "feathered edge" after sanding and a defined trace of filler will be seen throughout the final sanding stages

Sand away the filler material with 180 grit sandpaper and primer the entire surface. Give it a few hours to dry then sand with 220 grit sandpaper and prime again. Continue the process (i.e. 400 grit then 600 grit) then set the jaw aside. Final sanding will come at a later phase of production.

Still haven't worn yourself out yet? Okay, you know the drill; click the text below to continue.

MOVE ALONG, to Jaw to Dome Mounting